- Products

- Solutions

Solutions

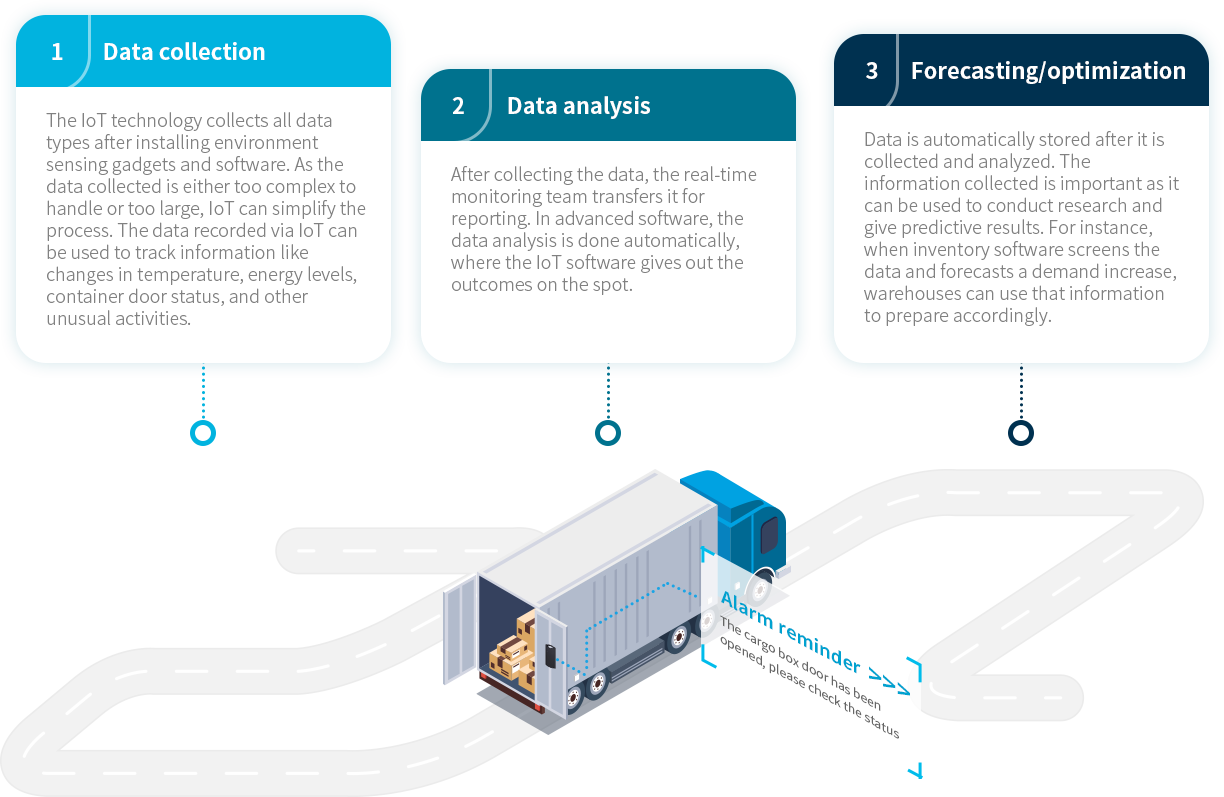

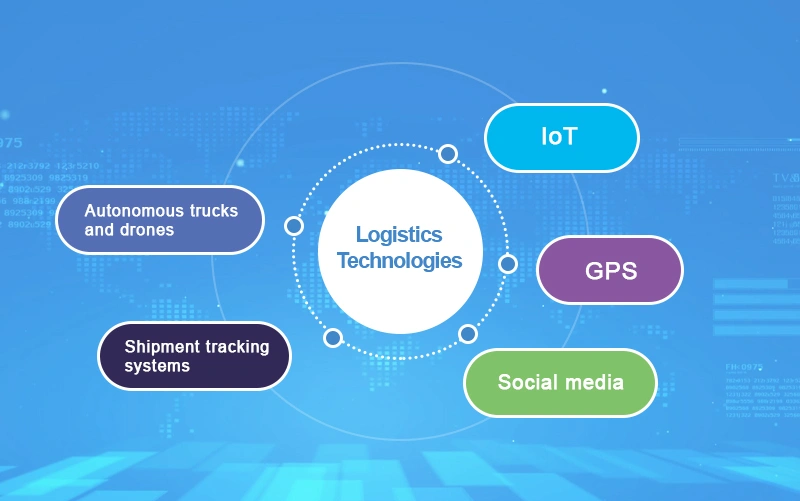

Harness the power of IoT with our smart solutions. Innovate and transform faster with our leading IoT expertise.

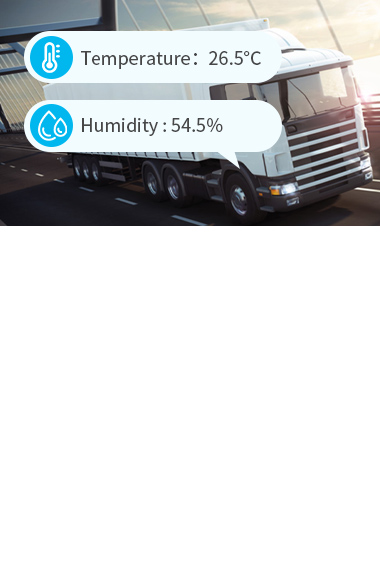

- Applications

Applications

Innovate without limits. Bring your boldest IoT vision to life with our versatile applications.

- Services

Services

Partner with us for success. Our exceptional services deliver results and value for customers and partners.

- Resources

Resources

Empower your IoT journey. Expert insights, news & events, documentation – find our wealth of resources.

- About

Why MOKO

The intelligent choice for IoT innovation. Our experience and technology lead the way.

- Contact