Today, the Internet of Things and supply chains are inextricably linked. As a matter of fact, logistics tracking is one of the most popular areas of the IoT. IoT in supply chain management is complex and high-risk – when things go wrong, it often has knock-on effects that affect the entire industry. IoT supply chain technologies rely on the visibility of materials and goods throughout the production and delivery process, helping managers from manufacturing to shipping and delivery, monitor logistics, optimize production, secure goods in transit, improve efficiency and customer service, and ultimately prevent bottlenecks in critical supply chain networks.

IoT sensors close the control loop of intelligent supply chain management and realize real-time asset monitoring of the entire supply chain. Sensors can evaluate many asset state variables, including temperature and vibration. All of this affects how today’s rugged sensors can withstand adverse conditions and continue to provide valuable data. As the capabilities of 5G networks expand, the Internet of Things supply chain will become faster and stronger.

What is the Internet of Things?

IoT refers to technology that connects physical devices via the Internet. Devices like thermostats, smart meters, smart switches, etc., obtain data from the environment and transmit it to the cloud. The system can analyze different types of data, such as temperature, state of something (such as on/off), geographical location, rate, etc.

It is estimated that Global big data analytics market will reach $68.09 billion by 2025, and the IoT connections worldwide have reached 13.6 zettabytes in 2019. But what to do with the data? How does this data help the Internet of Things in supply chain management? Read more about the “supply chain” below to answer your questions.

6 stages of the supply chain

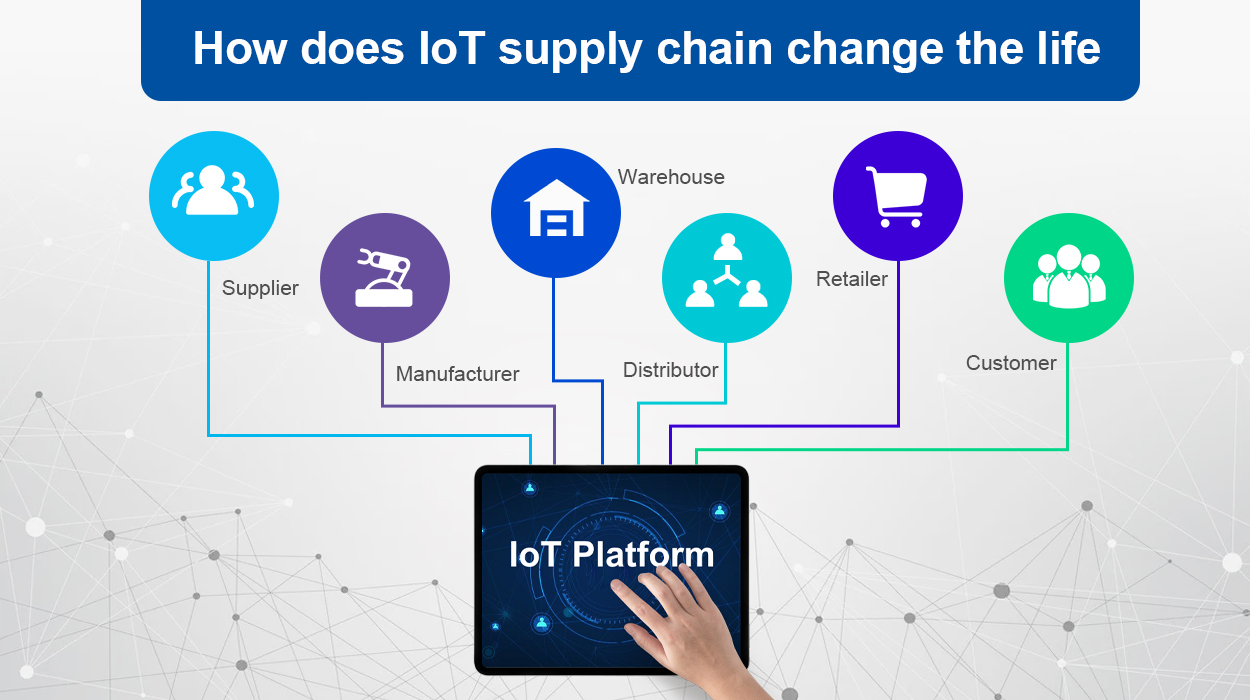

The smart supply chain IoT includes all the activities required by different groups or organizations to transform raw materials into finished services or goods and deliver them to the final consumer.

A streamlined supply chain management model consists of 6 stages:

-

Raw material supplier

This phase is one of the lowest levels of IoT solution implementation. Perishable raw materials produced by raw material suppliers such as ranches, commercial fisheries and farms need to be processed, packaged and then quickly transported to the next stage of the supply chain.

On farms, for example, the Internet of Things provides a variety of data through a network of connected sensors. Data like chemical applications, soil moisture, livestock health, and dam levels can be collected by IoT devices. Farmers are enabled by these data to maintain optimal conditions on their farms.

IoT devices can also alert when supplies run low. In addition, vehicles transporting perishable food require specific temperature controls, and IoT applications can send alerts when container conditions do not match specified parameters, avoiding unnecessary spoilage and financial expense.

-

Original equipment manufacturer /OEM

Manufacturers are the second stage. They turn raw materials and natural resources into commodities. IoT supply chains allow manufacturers to achieve maximum productivity, among other benefits. IoT systems enable data to be recorded manually and provide more timely and precise data from sensors.

Manufacturers are enabled by continuous monitoring to track hang times during manufacturing and assembly operations in real-time. This helps identify bottlenecks during production and make necessary adjustments. In addition, sensors can be helpful in detecting resource leaks, for instance, by identifying broken machines with relatively high energy consumption and replacing or repairing them.

In addition, IoT also opens the way for proactive maintenance by monitoring the health of the machine and notifying operators when maintenance is required. Timely maintenance reduces downtime as workers can deal with maintenance issues before the machine actually breaks down. Predictive analytics can save a lot of money by predicting system failures and machine failures.

Unluckily, the manufacturing process may bring out environmental pollution. This has led to climate change and the deterioration of living conditions. Through the IoT supply chain, we can integrate green strategies, such as controlling water use levels, reducing production waste, and implementing renewable energy. It’s possible to track pollution from all sources on earth using machine learning, big data approaches, and IoT in supply chains.

-

Warehouse

A warehouse is an organization that is allowed by law to store goods. Goods can include raw materials and manufactured goods. So warehouses are useful all around the supply chain. The warehouse obtains a real-time inventory tracking system by utilizing IoT sensors. Warehouses are able to easily monitor and make analyses on inventory levels, inventory locations, and goods moving in and out of the warehouse in real-time by placing sensors on all goods, materials, or products. The warehouse uses RFID sensors to track the good’s location within the warehouse and control whether products are moved to build such a robust inventory system.

Inventory management is a necessary tool to operate and optimize the supply chain with the Internet of Things devices. These systems guarantee the flow of products, deliveries and raw materials from producers to warehouses, and distributors to customers.

Asset management for supply chain management is significant. Without reliable data on inventories, distributors and transportation companies will not be able to ensure that their complex supply chain networks are functioning properly. However, the networks we are using today are seeking to respond quickly when demand outstrips supply.

IoT can be used for warehouse management to limit orders that cannot be fulfilled, update the inventory data in real-time, and track availability. Enterprises can deploy machine learning models to learn from repeated patterns in the Internet of Things device data and optimize processes to prevent avoidable shortages.

IoT sensors can provide real-time product maps, showing the order picking instructions and precise location information of the items in the order. It brings out better picking accuracy and decreases the amount of time required to finish the order. Environmental sensors help monitor storage conditions and maintain the safety of perishable goods. They control storage conditions levels of pressure, humidity, and temperature to notify managers if some of them fall below required levels, and can even adjust conditions automatically. In addition to this, some large warehouses could also benefit from the use of autonomous mobile robots (AMR) to almost fully automate their warehouses. AMR can detect obstacles and navigate around them with proximity sensors and cameras. In addition, the robot will analyze the environment and perform actions only if it is assured of success. The AMR robotic system can transport goods within a warehouse without human involvement.

-

Distributor

The distributor delivers the product from the manufacturer. The responsibility of the distributor is to ship the goods. They provide real-time data on the location of products and provide accurate delivery times for goods through the Internet of Things. By obtaining real-time information from operators, airlines, transit stations, port authorities, weather satellites and common satellites, the distributor can see the entire distribution route and optimize it by combining real-time data from different sources. In addition, if the cargo is delayed or there is some change in the route, the IoT system will immediately notify all relevant parties. The IoT supply chain provides total control over the entire route.

IoT sensors, such as RFID tags, can instantly access the contents of any package and its storage conditions during transport. This allows the delivery staff to track every item effortlessly, ensure that no packages are lost, and make the entire delivery process more transparent.

The IoT supply chain also brings benefits to the cryogenically controlled supply chain, also known as the cold chain. The cold chain involves the transport of perishable goods such as food, fish, meat, flowers or medicines – all types of goods are vulnerable to environmental conditions. With IoT sensors, any deviation from the recommended storage conditions is immediately detected and the dealer is notified by the IoT system. The Internet of Things solves obstacles for the cold chain, saving goods, public health and money.

-

Retailer

In this phase, the retailer sells manufactured goods transferred by the distributor to the end customer. IoT sensors accelerate the process of loading and unloading goods, as RFID tags retain all necessary information about the contents of any package, in this way, any third parties and retailers can get accurate information about each package in a delivery.

The IoT supply chain opens the way to new shopping technologies that do not require scanners, queues and checkout counters. Instead, you just grab an item you want to buy, and the IoT system will recognize your choice and automatically add the product to your chart. When you finish shopping and leave the store, the IoT system pulls the final cost of the item from your account.

There is eighty-two percent of retail executives were worried about shortages and fifty-five percent were ready to switch to secondary suppliers during the 2021 holiday season. Traditional inventory management may make it difficult to perform this process quickly enough to meet the high demand of the season. Using IoT technology, retail stores can immediately submit orders to distribution centers when their inventory reaches a minimum threshold.

-

The final customer

A customer is a person who buys a final product from a retailer and uses it for their own purposes.

5 IoT solutions in the supply chain

Organizations and businesses that invest resources in the implementation and research of practical IoT applications are the potential power to take full advantage of this trend. The shift away from the “offline” approach is already in full swing. For instance, global spending on IoT in logistics and transportation rose from $10 billion in 2015 to $40 billion in 2020. The current speed of technological development and all indicators point to more dramatic growth in the near future, with incoherent methods and structures becoming uncompetitive and quickly obsolete.

Equipment condition monitoring

Monitoring environmental conditions is an essential use case that demonstrates the value of IoT in saving time and resources. It’s always important to know what’s going on in the supply chain. For instance, if a product is required to be stored in a warehouse for a period of time, the temperature inside the facility should be known. Monitoring a facility has become a manual and time-consuming process recently. Someone must have access to the devices scattered around the building to download the data.

The Internet of Things has changed that. The latest products are now connected using LPWAN to transmit information to customers and the central platforms in real-time. You can also establish your system to send a message to customers whether there is any change in humidity or temperature.

At the strategic level, these data can be used to assess the general situation of warehouses and to inform future decisions regarding warehouse maintenance.

Cold chain monitoring

The COVID-19 pandemic put the Internet of Things to the test and passed. The unprecedented surge in vaccine development calls for rapid and safe delivery of vaccines worldwide. When BioNTech announced that its vaccines needed to be transported at temperatures of -70°C, the logistics company was responsible for developing the solution to provide end-to-end visibility into the vaccine cold chain. Cold chain monitoring utilizes connected devices to monitor each shipment and track its condition throughout its journey.

In addition to vaccines, many medicines do not do well in humid and hot conditions. This means they must be transported and stored in a temperature-controlled environment. However, customers have to make sure the products stay within a certain temperature range. IoT devices such as LW002-TH record and report conditions according to customer requirements, and the system detects deviations beyond specified parameters.

This visibility ensures product stability, not to mention accurate reporting like audits. We believe the IoT value in cold chain logistics will only grow as growing numbers of treatments and drugs are developed that require lower and lower temperatures.

Monitor transportation safety and prevent loss

Freight monitoring today goes far beyond simple track and trace. IoT is emerging as a key enabler of logistics and supply chain security and loss prevention. We can now monitor the movement of goods in warehouses or distribution centers and throughout the supply chain with the GT001 Goods Monitor tracker and LW007-PIR LoRaWAN PIR Motion Sensor. We are able to observe goods from the moment they are delivered to their final destination when everything is networked and online.

It’s been a long time since devices are using GPS technology, but it’s until recently have the ability to add real value to logistics. With long battery life, strong signal strength, and small size, it is the perfect solution for loss prevention and quality control in small package transportation. Today’s devices come in all sizes and shapes and can detect humidity, temperature, vibration, light, and more.

For instance, we can tell if there is excess light in the bag with a light detector.

For goods that are tiny, it’s hard to recognize them or know they’re inside. IoT devices can locate lost goods in the case of theft.

Forecasting inventory technique

Intelligent collection of data over time, pattern analysis, able to accurately predict and intervene if wrong operations occur. This offers production, purchasing managers, and inventory planners more information and forecasting accuracy while purchasing, manufacturing and selling products.

For example, Hardware retailer ACE Hardware utilizes IoT solutions to monitor product orders and shipping status. “IoT sensors allow real-time point-of-sale analysis, which allows ACE to replenish inventory systems in a faster way.

Maintenance & Repair

IoT-powered solutions can obtain data on humidity, temperature, machine faults, etc. It can be utilized to monitor real-time visibility and operations. Photographic instruments can scan machine parts such as blades, send alerts, and perform predictive maintenance. Hence, production facilities that integrate sensor networks into machines can enhance the overall quality of service while decreasing operational costs and increasing uptime.

For instance, GE Digital has adopted a solution that uses its sophisticated event processors to transform raw simplified machine data combined with RFID into process quality characteristics and actionable components.

GE can detect early defects and perform intelligent, unplanned maintenance by analyzing the vast number of RIFD sensor data generated during the production cycle. This has helped GE significantly increase output from its manufacturing operations.

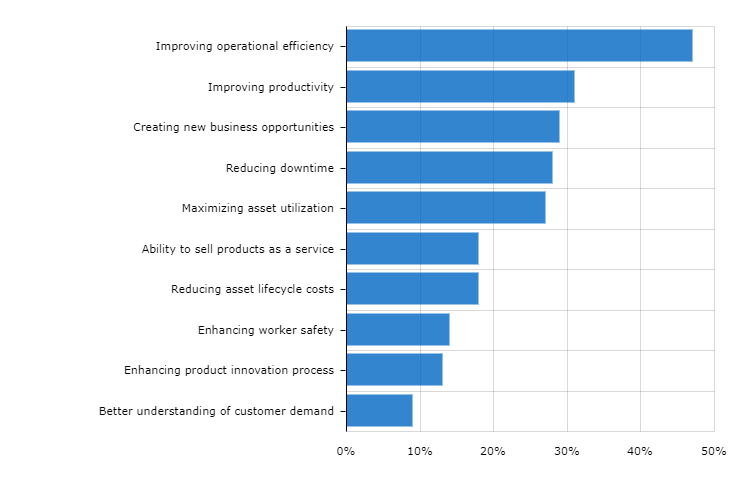

The benefits of IoT supply chain

As the IoT grows in popularity, more businesses are struggling to reap the benefits of the technology in their supply chains. If you want to know how the Internet of Things can reduce operating costs and enhance your company’s efficiency, here is an overview of its benefits in SCM.

Higher speed

IoT tracking technologies and smart route planning tools have greatly increased the speed of the entire supply chain. By integrating these technologies into daily operations, managers shorten feedback cycles, benefit from faster decision making, proactively reduce the risk of delays, and overall improve the efficiency of locating goods in the warehouse.

Higher accuracy

Connected platforms are much easier to obtain than closed systems. By building cloud-based IoT systems, companies can ensure that all parties in the supply chain lifecycle have access to relevant data and solve problems quickly. In addition, mobile and web tools for different users (customers, managers, employees, carriers) can help them gain insight and use the collected data to develop strategies and different scenarios related to needs and user roles.

Increased flexibility

IoT provides managers with detailed insights into commodity turnover, helping supply chain managers and retailers know how many units of each product to order. IoT also decreases the impact of human error by adding high precision to transportation, navigation, and asset tracking for drivers.

Better segmentation

Combining SCM and IoT is a great way for retailers to better understand their customers and products, and needs and develop relevant strategies. The data obtained during the product cycle helps to better understand the market and aim customers for a segmented product.

To improve efficiency

IoT offers various interconnected platforms for employees. Tools like smart glasses help guide warehouse workers seamlessly, ensuring they complete tasks in less time. Furthermore, IoT captures efficiency-related data and enables more awareness of labor and resource management. Thanks to this technology, the supply chain manager will make sure that all parties involved in the delivery are at their best.

Challenges of using the Internet of Things in logistics and supply chain

There are many companies still adopting outdated legacy systems to track assets and manage delivery despite the increasing need for digital transformation. Many of the issues associated with outdated operational technologies and practices can be addressed by leveraging IoT in the supply chain. But there are still many challenges to IoT implementation.

-

The skills gap

Adapting to the management link system requires intensive training of warehouse workers and vehicle drivers. Explaining security practices and outlining guidelines for using a company’s platform is a time-consuming process.

-

Added data storage challenges

Large data pools are one of the many strengths the IoT offers supply chain managers. At the same time, however, there is a need to acquire sufficient server capacity to store and process all the collected data. Company managers are required to develop data governance policies and seek out analysts and data scientists to make sure they are drawing the correct conclusions from IoT-based insights.

-

Security threats

Building a secure architecture is another goal that supply chain managers must address.

-

The connection is faulty

The Internet of Things relies heavily on a stable Internet connection. As fleet drivers move from place to place, there is not always a reliable network. As Internet coverage expands and 5G becomes more widely used — and the connectivity problem may ease on its own — supply chain managers are having to live with it for now.

Bandwidth is another issue to pay attention to in the IoT supply chain. Connected platforms typically consume a lot of bandwidth and an advanced server farm is required to run smoothly.

Use cases of IoT supply chain

Global brands push the IoT and supply chains to the forefront. Here are some examples of how large businesses are benefiting from the Internet of Things in their daily lives:

- Amazon

Amazon specializes in using IoT devices in its supply chain and integrated a series of Internet-connected robots for warehouse management in 2012. By implementing IoT in its warehouses, Amazon uses human resources more efficiently, allowing people to focus on tasks like packaging, packing, or inventory management.

- Volvo

The company is utilizing a networked cloud system to track shipments of auto parts from different countries. Volvo utilizes the IoT to track deliveries of cars to its international suppliers.

- Nissan

Carmaker relies on the Internet of Things to connect industrial plants automatically. The company is using an intelligent warehouse management system at its plant in England.

- New Maersk Line

Maersk is also a premium company as one of the leaders in logistics and shipping services while looking for advanced IoT supply chain user cases. The Danish company adopted a remote container management system that can monitor the temperature and humidity inside the container, decreasing resource waste and food spoilage. The platform enables operators to monitor environmental conditions and enhance the precision of transportation implementation and planning.

How can IoT help the supply chain during COVID-19

Managing a business during COVID-19 is not that easy. Dealing with the entire supply chain during a global pandemic is a bigger challenge. IoT devices are a godsend for many businesses, helping to track assets in inventory. Two of those industries are health care and food. Both areas need consistent environmental conditions during transportation. Both sectors are at the forefront as the pandemic keeps redefining everyday life as we know it.

Assist supply chain

The details matter for the food and healthcare industries. Medical instruments and samples as well as perishable food must always be kept under strict conditions. Companies have turned to IoT devices such as asset tracking and GPS to obtain data.

Asset trackers measure variables such as temperature, humidity, orientation, and vibration to ensure inventory remains in the desired environment. If errors in Settings keep happening, you can use IoT data to look for patterns and hopefully find a solution.

At the same time, GPS trackers help companies collect data about their shipping routes and use that data to maximize efficiency. Supply chain managers are enabled to make adjustments as the tracker shows inventory in real-time. It’s reported that Mondelez and Kraft-Heinz have started using these devices in their supply chains.

Building consumer confidence

IoT devices not only enable inventory to flow smoothly throughout the supply chain, but they also enable companies to audit the process and guarantee quality. That is capable to enhance consumer confidence. Consumer confidence in food quality and safety lags far behind perceptions within the industry in the beverage and food industry. Only 35 percent of consumers believe the industry is ready to manage food transparency and traceability, compared to 69 percent of industry insiders.

Companies are deploying Internet of Things devices in their supply chains to close the gap. In addition, the industry is using trace and tracking solutions that enable them to confidently cite the source of their food. Tracking and tracing also allow companies to bring safer products to market. By knowing exactly how long it takes a product to travel from the production site to the sales counter, companies can better prevent expiration and contamination, which are top safety concerns for consumers, Zebra Technology said.

The future of IoT in supply chain management

The edge computing solutions in supply chain management will enable it easier to collect, process, and process data from the Internet of Things devices as telecom providers build 5G networks. This bright future will enable various high-level use cases more widely accessible:

- Evaluate products for damage and defects.

- Verify the authenticity of products at every stage.

- Provide shareable visibility across supply chain networks for business entities and consumers.

- Establish an intelligent warehouse with efficient inventory management.

- Reduce supply chain costs, reduce product and raw material waste, and transportation congestion.

Explore MOKOSMART IoT solutions

Understanding the IoT in manufacturing today and how technology is changing supply chain management provides insight into improvements yet to come. Currently, the intersection of IoT supply chain solutions is not new – it is the next stage of technological advancements that have progressively driven the industry to this point.

But the leap that many organizations are making – connecting their Internet of Things devices to centralized management platforms – will dramatically enhance the functioning and health of the global supply chains on which every industry depends. Contact us to start a conversation about your IoT projects or learn more about how our IoT solution can be helpful in alleviating today’s supply chain bottlenecks.