COVID-19のパンデミックは、ロジスティクスなどのほとんどの業界を混乱させました, 製造, とサプライチェーン; 技術は技術の進歩とビジネスの安定性にとって重要な要素のようです. ロジスティクスにおけるIoTは、輸送プロセスに透明性を組み込むことにより、輸送技術をより高いレベルに引き上げました, 運用プロセスの改善, と商品の配達を加速します.

MOKOSmartにて, 集まるインターネット対応スマートデバイス向けのソフトウェアとハードウェアの開発を提供します, 彼らが彼らの環境から得た情報を送り、それに取り組む.

スマートプラグ

EV充電

Power & Energy Meter

Bluetoothビーコン

LoRaWANセンサー

接続されたエコシステムは、ロジスティクスプロバイダーが遠隔地からの車両を追跡するために確立されました. 商品が時間通りに目的のエンドポイントに到着することを確認します.

以下はトップです 5 エンドツーエンドのサプライチェーンを効率的に管理するためのロジスティクスにおけるIoTのユースケース.

資産追跡は、ロジスティクスと輸送におけるIoTの最も一般的なユースケースであり、資産管理です. このアプリケーションにより、ユーザーは在庫資産をリモートで追跡できます, 彼らの位置を監視する, すべての変更をすばやく取得します. しかも, 車両にIoTセンサーを組み込むことで、輸送の過負荷と過少負荷を回避できます.

IoTシステムは、ロジスティクス会社の日常業務をリアルタイムで監視します. しかも, また、交通ルートの最適化を可能にし、制限やポリシーの変更などの要素を考慮します.

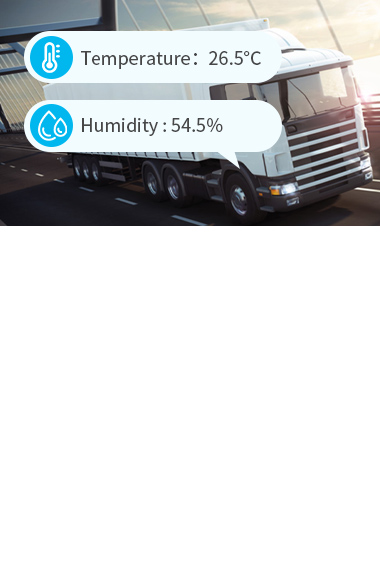

IoTテクノロジーは監視に役立ちます, 維持, ロジスティックシステムの温度を調整します. この個別のアプリケーションは、生鮮食品や医薬品での使用に不可欠です。. IoTテクノロジーによって駆動されるセンサーは環境データを収集します, 圧力など, 温度, 湿度, 露光, もっと, したがって、環境条件の簡単なリモート監視と制御が可能になります.

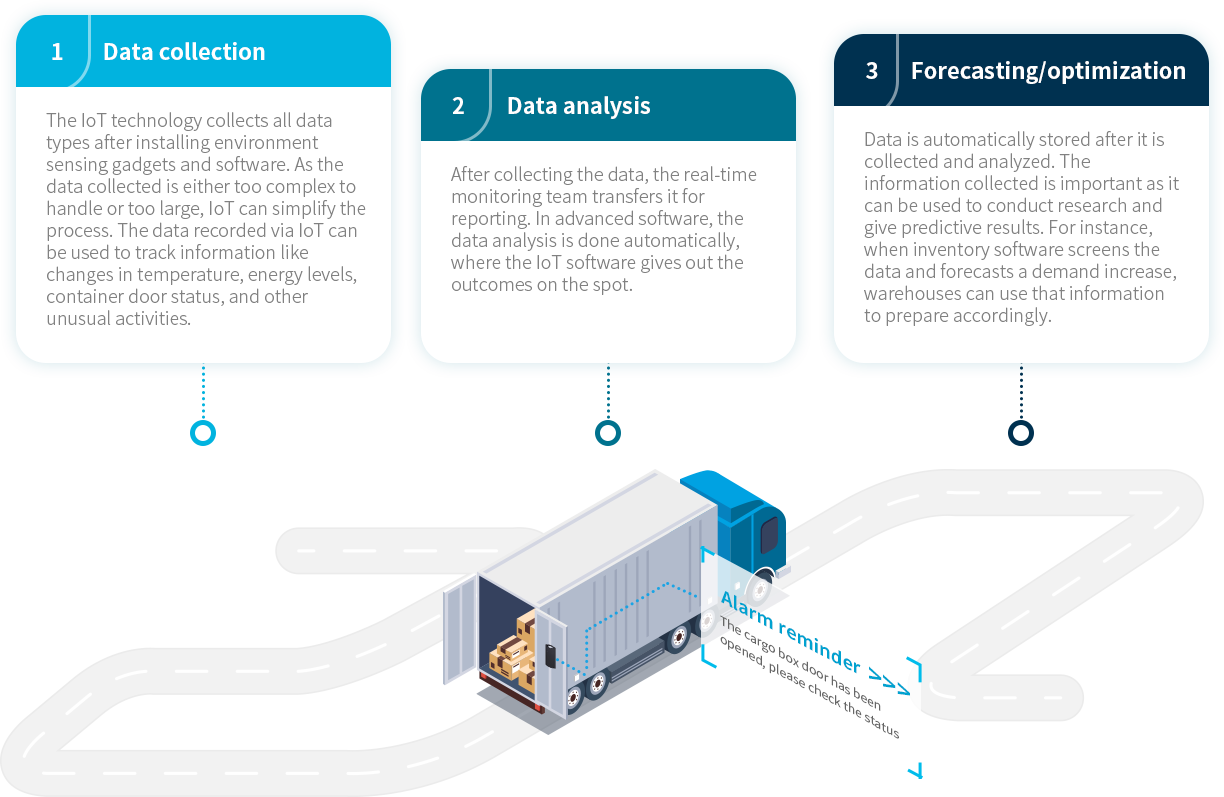

IoTロジスティックシステムは、さまざまなリアルタイムメトリックを取得できます; 収集されたデータを分析し、予測結果を出します. 例えば, リアルタイムデータの絶え間ない流れで, ロジスティックシステムはよりスマートな配達を計画できます, ルートを調整する, 何かがうまくいかない前に弱点を認識します. しかも, 彼らはまた、無能な機器の使用法や事故を予測することができます.

IoTセンサーを輸送システムに組み込んで、輸送プロセスに関するリアルタイムの情報を送信できます. したがって, IoTシステムは、配達の位置を単一のユニットまで追跡し、道路交通や車両の位置やステータスなどの予期しないイベントが発生したときにユーザーに通知することができます.

IoTデバイスは、センサーを使用してデータを収集および通信できます, スケーラブルなクラウドソリューション, とユーザーフレンドリーな通信システム. ロジスティクスにおけるIoTの利点は次のとおりです。;

スマートルートを計画するためのIoT追跡ソリューションとツールは、サプライチェーン全体の速度を向上させます.

閉鎖系よりも接続されたプラットフォームに簡単かつ迅速にアクセスできます. 企業がクラウドベースのIoTシステムを構築する場合, サプライチェーンのすべての関係者が問題に迅速に対処し、重要なデータにアクセスできるようにします.

IoTは、ロジスティクスマネージャーに良好な売上高の包括的な認識を提供します. これにより、サプライチェーンマネージャーとセラーは、すべての製品を注文する必要があるユニットの数を決定できます。.

サプライチェーンサイクルで収集されたデータにより、マネージャーは市場とセグメントを明確に理解できます, ターゲットオーディエンスを考慮して.

IoTにより、多数の接続されたプラットフォームをワーカー向けに調整できます. スマートグラスなどのツールが倉庫の従業員に指示します, タスクの完了に最小限の時間を費やせるようにする.

自動注文の処理とステータスの更新により、企業は配送スタッフの数を減らすことができるため、全体的な運用コストが削減されます。.

IoTは企業に多様なデータを提供します. したがって, ロジスティクスマネージャーは、このテクノロジーを適用して、サプライチェーンの運用を正確に計画し、ビジネス上の意思決定の結果を予測できます。.

サプライチェーンマネージャーは、ロジスティクスで幅広いIoTアプリケーションを使用して、運用の処理方法の全体像を把握できます。.

IoTデバイスは、センサーを使用してデータを収集および通信できます, スケーラブルなクラウドソリューション, とユーザーフレンドリーな通信システム. ロジスティクスにおけるIoTの利点は次のとおりです。;

MOKOSmartにて, お客様が完全なロジスティクスインフラストラクチャを簡単に追跡および監視できるように、IoTソフトウェア開発およびコンサルティングサービスを提供します. 輸送プラットフォームにフル機能のIoTを適用することを期待しているクライアントにカスタムIoTアプリケーション開発サービスを提供します. MOKOSmartで利用可能ないくつかのIoTソリューション開発ソリューションには次のものがあります;

お客様のニーズに合ったテクノロジーの選択を支援します. しかも, 組み立ても承っております, 設計, プロトタイピング, カスタムハードウェア開発を必要とするソリューションへのサービスのテスト.

IoTおよび接続デバイス向けの豊富な機能を備えたソフトウェアを提供します. 当社のシステムは消費電力要件を満たし、信頼性と安全性が大幅に向上しています.

クラウドとフィールドをローカル処理に体系的にリンクするIoTゲートウェイデバイスを開発します.

Bluetoothビーコンなどのさまざまなホワイトラベル製品を使用したホワイトラベルソリューションを提供します, スマートホームデバイス, フィットネストラッカー, 等, 世界のスマートデバイス市場向け.

ロジスティクスなどの資産集約型産業におけるIoTの実装, 製造, 交通機関は比較的高いです. 固定からモバイルアクセサリーまで, これらの資産はすべて、接続されたシステムの一部として出現しています。, 重要な情報を共有し、接続する場所. トラックや船舶などの委託車両は、IoTネットワークの重要な部分であるモバイルプロパティです. 彼らは、ロジスティクスおよび輸送業界に永続的な空洞を残しています.

モノのインターネットが登場する前でも, 輸送, ロジスティクス, と倉庫業は、組み込み接続システムにつながる主要な推進力でした. ロジスティクスにおける高度なテレメトリスキルとIoTの監視ソリューションの存在により、テクノロジーは業界を垂直に進化させることができました. しかも, その世界につながる市場は急速に発展しています. に 2016, 市場のグローバルな価値は $10.04 十億, 現在、時価総額は $41.30 の終わりまでに10億 2021. これは、年間の総進捗率です。 32 パーセント. 間違いなく, IoTロジスティクスのセクターは祝福です. その制定により、ロジスティクス業界はその手口を変革することができました. しかも, それはまたより高い結果を得ています.

サプライチェーンの統合は、現在の貿易政策を順守することを構成するだけではありません。, 企業は、データサイロを回避するために、サプライチェーン内にすべての重要なプラグを組み込む必要があります. これとともに, 柔軟性の向上は、ロジスティクス業界で経験された最も重要な課題の1つです。.

高度なテクノロジーがクライアントの期待に変化をもたらしました. さらに, クライアントが十分な情報を持っているとき, 彼らは、ロジスティクスサービスがプロセス全体を通して完全に情報を提供し続けることを確信しています.

ITシステムに関しては, 多くの輸送企業はまだ苦労しています. しかも, 進化するデジタル要件に関連する主な課題は幅広い. ほとんどの企業は、以前の問題を解決する前に、次のデジタルバンドワゴンに移行することに焦点を当てています.

デジタルトランスフォーメーションには、このデジタル時代に完全に経済的であり続けるためにビジネスを行うためのモデルとアプローチを改革することが含まれます. しかしながら, デジタルトランスフォーメーションに合わせてロジスティクスプロセスを刷新できなかった場合、ビジネスを遂行する機会が不十分なため、収益と利益が減少します。.

運輸会社は自社のコアシステムを知る必要があります. 彼らのビジネスを混乱させる前に, これらの運送会社は、優れたアーキテクチャを開発することが多いため、コアシステムを認識する必要があります。.

運送会社のハッキングは頻繁に発生します, しかし、ほとんどのサイバー攻撃は内部から発生します. これは、従業員が内部のオープンな脆弱性を提供することによって引き起こされます. 確立されたサイバープロトコルに従わない従業員は、これらの脆弱性を引き起こします.

ロジスティクス企業は、ユビキタスなデジタルテクノロジーにもかかわらず、アナログチャネルを介して注文を受け取ることがよくあります。. したがって, 注文を迅速かつ効率的に処理し、出荷の詳細を記録することはより困難になります.

ロジスティクスと輸送におけるIoTの課題のいくつかは、次の点に注意する必要があります。;

会社に対応するソリューションを作成できる熟練したチームを見つけるのは難しい場合があります. ロジスティクスにおけるIoTには不十分な専門的トレーニングが不足しています. グローバルなテクノロジーの才能がないため, 経験豊富な専門家の採用には時間がかかります.

かさばるデータプールの強みは、収集されたデータを分析および保存するための適切なサーバーパワーを取得することです。. 会社のロジスティクスマネージャーは、データアナリストに知識を求めて、適切な結論を導き出す必要があります。.

すべてのプロセスを接続されたプラットフォームに移行する前, サプライチェーンマネージャーは安全なアーキテクチャを構築する必要があります. データ処理とストレージの脆弱性は、障害のコストを増加させ、外部のデータ攻撃と漏洩を引き起こす可能性があります.

安定したインターネット接続は、すべてのIoTアクティビティに不可欠です. ある場所から別の場所にフリートが移動するため、信頼できるネットワークが常に利用できるとは限りません。. インターネットカバレッジの急速な増加と5Gネットワークの可用性, 接続の問題がそれ自体を軽減する可能性が高くなります.

IoTが利用可能にする指数関数的な膨大な量のデータは、その主要な資産の1つです. このデータには、接続されたサプライチェーンに関する貴重な情報が含まれている場合があります。, 管理と分析をせずに収集するだけでは不十分です.

運用管理チームとITチームは、接続されたサプライチェーン用のIoTデバイスを購入するために社内で苦労しています. 例えば, ITチームは、市場に出た直後に最新のIoTテクノロジーを入手したいと思うかもしれません。, しかし、運用チームは余分なコインを使う気がないかもしれません.

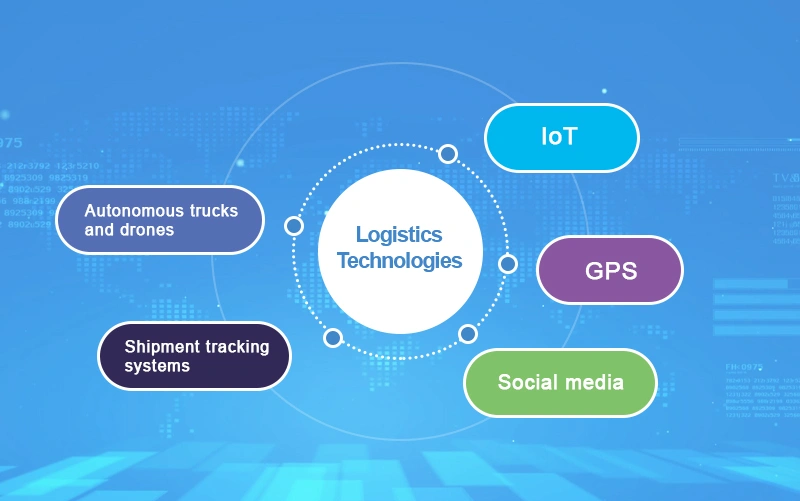

技術の進歩により、サプライチェーンの生産性は急速に向上しています。. しかも, 企業のテクノロジーの向上により、コストとエラーが最小限に抑えられます. ロジスティクス業界がその課題に対処するのに役立つ5つの主要な最新の高度なテクノロジーを以下に示します。.

技術の確立以来、IoTデバイスの精度は根本的に向上しました. それはサプライチェーンを改善するのを助け、欲求不満を助けました, 失われたドライバー. GPS精度の向上は、貨物の位置を追跡することで顧客を満足させ、生産性を向上させます. また、再構築された交通データへのアクセスを介して運搬を改善します.

モノのインターネットは、コストの最小化やリスクの回避など、複数のサプライチェーンの機会を生み出します. 例えば, センサーなどのIoTデバイスは貨物船に搭載されています, タクシー, 電車, 等, センサーが警報システムに接続されている場合、貨物の追跡と監視を支援します. センサーは収集されたデータを分析してチームに伝達し、隠された脅威に気づきを与えます. IoTはロジスティクスの未来に大きく影響します, 比較的新しい技術ではありませんが. これにより、商品をより正確に配達する時間と輸送中の可視性が可能になります.

ソーシャルメディアの力は、ロジスティクス業界の業務を大幅に最適化します. これらのプラットフォームにより、企業はクライアントと効率的に通信し、緊急の情報と顧客のフィードバックを迅速に送信できます。.

最初は, クライアントは配達を予約します, 配達予定日を受け取る, その後、電話をかけて貨物に依頼しない限り、貨物の進捗状況に関する情報はありませんでした。. 現在のところ, インターネットとソフトウェアの進歩により、クライアントは追跡および出荷システムに簡単にアクセスできるようになりました. これにより、会社の時間とお金が節約され、ユーザーエクスペリエンスが向上します。.

コンピューターを使ってある地点から別の地点まで運転したり、高騰する空中の乗り物から荷物を受け取ったりするのは映画の外のように聞こえますが, それが私たちが向かっているところです. 実際には, 自動運転車はすでに設置されています, トラックはそれほど遅れていません. 自動運転車は完全に無人ではありませんが, これは、配信プロセスの生産性を最大化できる画期的なテクノロジーです。.

国際的なブランドは、サプライチェーンとモノのインターネットをつなぐ最前線にいます. 以下は、IoTが大企業に日常的にどのように役立つかについてのいくつかの例です:

アマゾンは、サプライチェーンでのIoTデバイスの優れた使用でよく知られています. に 2012, 同社は、倉庫を管理するために多数の接続されたロボットを組み込みました. 自動化されたテクノロジーは、QRコードをスキャンして小包の製品を認識する役割を果たします. 低電力ワイドエリアネットワークに依存するAmazon埋め込みIoTデバイス (LPWAN) 倉庫で人間の労働力を生産的に活用する.

同社は、接続されたクラウドベースのシステムを使用して、さまざまな国からの自動車部品の配送を監視しています. Volvoは、セルラーネットワークに依存するワイヤレスIoTセンサーを使用して、会社のグローバルサプライヤーへの車両の配送を追跡します.

Nissan Companyは、NissanConnectの一部として提供される標準機能としてBluetoothテクノロジーを導入しました. Bluetoothサポートの使用, これで、スマートフォンと車をペアリングできます. それはあなたが簡単にハンズフリー通話とテキストメッセージングを行うことを可能にします.

Maerskは、高度なサプライチェーンIoTアプリケーションを探す際に考慮すべき企業です. セルラーまたはNB-IoTテクノロジーを介して配送コンテナ内の温度と湿度レベルをリモートで監視するリモートコンテナ管理システムの開発を試験的に実施しました. これにより、資源の浪費が最小限に抑えられ、食品の腐敗が減少します. このプラットフォームにより、労働者は生態系の状態を簡単に監視でき、ロジスティックの実装と計画の精度が向上します。.

モコスマート

有名な IoT ソリューション プロバイダーの巨人として, MOKOSmartは、あなたのプロジェクトが業界をリードしていることを保証できます. OEMまたはODMサービスを提供するために私たちを選んでください.

私達と接続