omlox

China Seminar 2023 Invitation

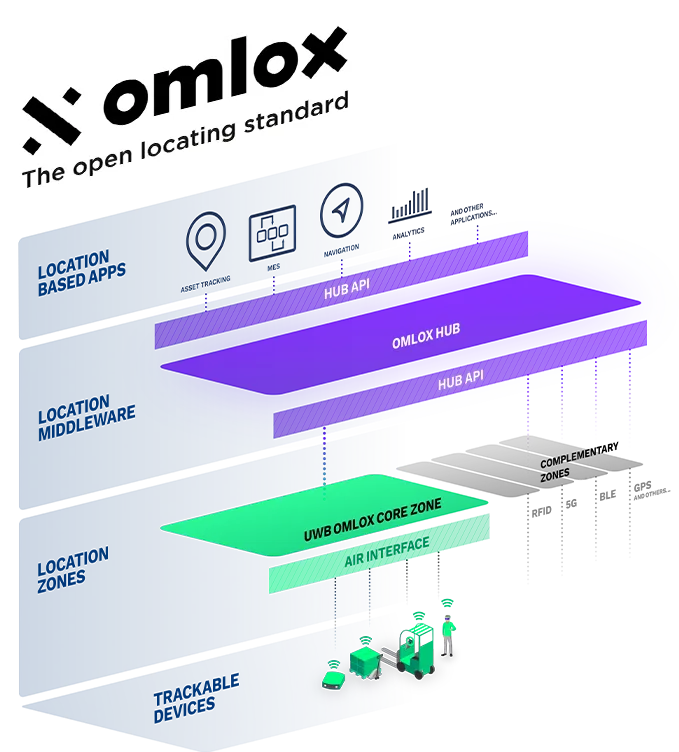

Seamless Integration of Location-Based Services

In our daily lives, location-based services have seamlessly integrated into our routines. For instance, everyone relies on navigation systems for driving, or shares their location with friends and family to facilitate quicker meet-ups. These functionalities hinge on wireless communication and positioning technology, which acquires and processes the specific locations of objects, thereby providing greater convenience to our lives. As the significance of “where” continues to grow apparent, people are also shifting their focus towards applications in industrial settings, striving to elevate automation to an unprecedented level through the comprehensive utilization of positioning systems.

In the era of information IoT (Internet of Things), data become the primary source of productivity. Only through digital transformation and the transparency of data in the production process could we break through the optimization bottleneck of traditional production capacities. Inefficient layouts often lead to low efficiency in internal logistics or production. For example, employees might waste a significant amount of time and effort from issues of workflow in their daily tasks, or the less-than-optimal routes chosen for forklifts and the placement of materials. If the real-time status of these situations could be accurately reflected through data and thus enabling the analysis and identification of inefficiencies, managers could scientifically implement corresponding improvements from a holistic perspective. While achieving this automation, they could then proceed with further upgrades to these dynamic processes. The benefits generated will bring forth sustained competitive advantages to the long-term development of the enterprise.

Challenges in Real-Time Positioning Systems

While it may appear simple in theory, implementing a real-time positioning system that accurately displays the location data of various entities, such as people, vehicles, and objects, proves to be a challenging task. Currently, there are thousands of location-based applications, each employing custom solutions based on different positioning technologies, which result in data silos within the enterprise’s information technology processes. Factors impeding the real-time data collection of the positioning system include:

- Insufficient interfaces suitable for industrial applications;

- Absence of interactive-operable hardware;

- High costs associated with infrastructure and positioning tags;

- Expensive installation and integration costs;

- Existing data structures that lack standardization.

The innovative industrial-grade open positioning standard, omlox, significantly alleviates these challenges. With omlox, it becomes possible to seamlessly integrate location data from all positioning technology systems through middleware, while also enabling hardware interaction within the ultra-wideband range.

Empowering Industry with the omlox Standard

From a user perspective, the open interfaces of omlox not only reduce the risk of supplier lock-in, but also enable the synergistic use of multiple positioning technologies within a single positioning middleware. This allows enterprises to more flexibly adapt to diverse application scenarios. By integrating and accommodating various existing software and hardware solutions within the positioning industry, the positioning system under the omlox standard also possesses unlimited potential for upgrade and optimization.

A foreseeable outcome is if all suppliers in the market manufacture products according to the omlox standard, software and hardware solutions from different suppliers could become seamlessly integrated with one another. For the users’ perspectives, they would not encounter the inability to to find a suitable positioning system, as they can always flexibly combine a set of the most suitable positioning systems based on their own needs. Furthermore, if users find that the installed positioning system can no longer meet their current requirements, the additional costs of replacing system components to meet these new demands would also not be excessive. This is because industry standardization ensures that all products are mutually compatible, thereby significantly reducing the cost of switching suppliers.

In summary, an open positioning technology standard can empower the digital transformation of users in the industry towards intelligent production. With more effectively combined positioning solutions, enterprises could engage in lean production more flexibly, thus enhancing their competitiveness when responding to market changes.

Hands-0n Experience With MOKO

In order to provide a deeper understanding of omlox to domestic and international users, as well as industry colleagues, the omlox China team is scheduled to host its first offline seminar on December 8th, 2023 at the Grand Skylight International Hotel Guanlan in Shenzhen. We sincerely and are pleased to cordially invite you to attend this seminar. In addition to speeches by omlox member units from different positioning technology fields, this seminar would also include a visit to the factory of MOKO Technology Ltd. located in Longhua District, where you could experience firsthand the digitalization upgrade effect brought about by the integrated solution based on the omlox standard.

As a leading IoT device supplier in China, MOKO Technology Ltd. not only produces high-quality products but also maintains advance-level manufacturing and internal logistics. In this case, omlox used standardized interfaces to integrate UWB, BLE AoA, RFID, and outdoor GPS in different scenarios, optimizing the production and logistics processes of the factory to its greatest extent and achieving a high return on investment. To witness the effectiveness of the integrated solution and the reasons behind specifically selecting various positioning technologies for different scenarios, we welcome you to experience the charm of the omlox standard together.

Seminar Agenda

- 09:30 — 10:30

- 10:00 — 10:30

CAICT : omlox standard's role in empowering asset identification whitepapers

- 10:30 — 11:00

Address by President of omlox China - Yan Wang

- 11:15 — 12:00

Fuwit: ldentification technology and real-time positioning

- 12:00 — 13:00

- 13:00 — 13:45

ReliableSense: Case studies of omlox integration and high-level applications

- 13:45 — 14:30

- 14:30 — 16:00

- 16:00 — 17:00

Register Now

Please make sure to register for the seminar by scanning the QR code or

visiting the link, after completing the registration, our organizing staff will call you one week before the seminar to confirm your attendance.

Scan the code or

click the link below to register

We look forward to meeting you on December 8th!

- Seminar address: Grand Skylight International Hotel Guanlan