The cold chain industry is undergoing a major transformation driven by the Internet of Things (IoT). The global cold chain logistics market is projected to surpass $892.6 billion by 2030, as demand surges for safe handling and transportation of temperature-sensitive goods. However, ensuring ideal conditions in cold storage warehouses and refrigerated transport has always proved complex and costly. This is exactly why IoT solutions are emerging as a game-changing opportunity for supply chain leaders around the world.

What is cold chain logistics

Cold chain logistics refers to the specialized handling, storage, and transportation of temperature-sensitive products along supply chains. This involves meticulously maintaining prescribed temperature ranges from the point of manufacture to final delivery. An unbroken cold chain ensures that products do not perish, degrade or get contaminated throughout their shelf life.

Key aspects of cold chain delivery include:

– Refrigerated processing, packing, and storage facilities

– Insulated trucks, reefers, and containers for transportation

– Precise temperature and humidity control settings

– Real-time sensor monitoring and alert systems

– Contingency plans for equipment failures or delays

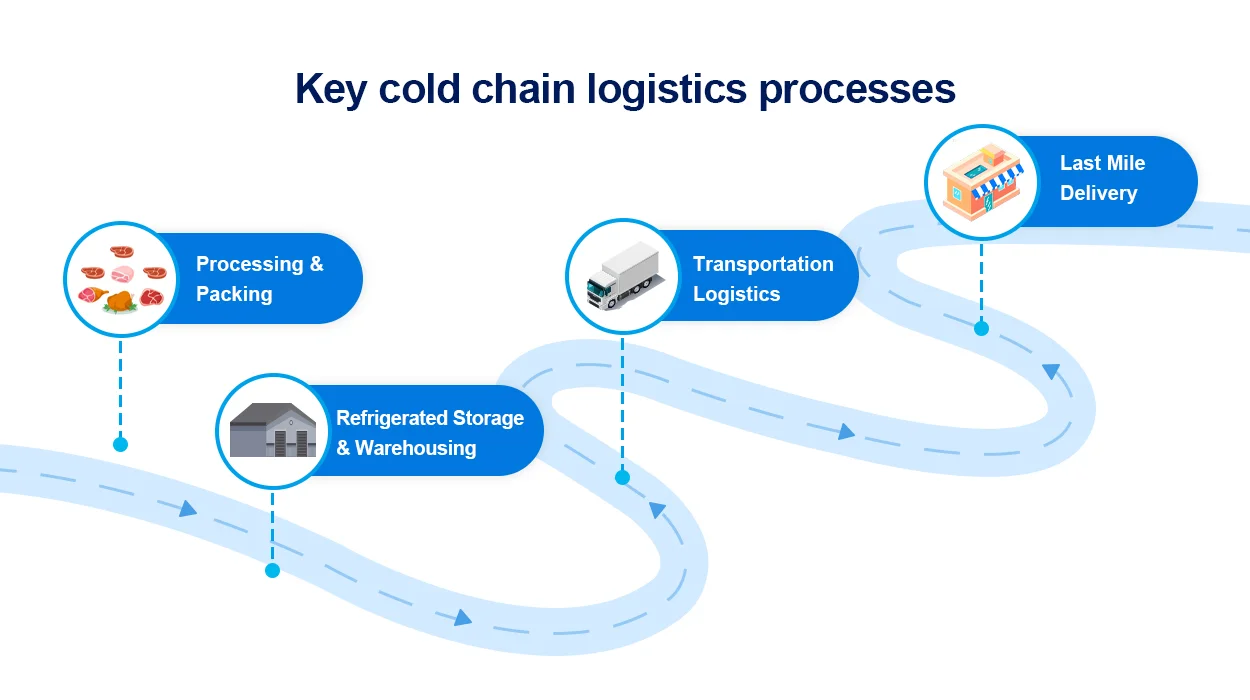

Key cold chain logistics services processes

Typical cold chain workflows involve tightly coordinated handoffs between multiple specialized stakeholders. At every critical control point, IoT improves control and visibility of cold chain integrity. Core cold chain management processes include:

Processing & Packing

Products are harvested, processed, graded, packaged and palletized in temperature-controlled environments. IoT sensors can track ambient conditions, equipment performance, and alert teams about inconsistencies.

Refrigerated Storage & Warehousing

Perishable inventory is stored in cold rooms, freezers or other climate controlled spaces. IoT monitoring provides full visibility while automating systems with connected sensors and alarms.

Transportation Logistics

Reefers, insulated trucks and containers with cooling mechanisms ship products between ports, warehouses, and retail outlets maintaining temperatures. Location GPS trackers and sensors allow remote in-transit monitoring and fleet oversight.

Last Mile Delivery

The final leg from logistics hubs to stores and end-customers is crucial. IoT tracking devices safeguard sensitive items right up to the point of consumption.

How IoT transforms cold chain logistics

Cold chain operators struggle with limited cargo visibility, changing ground realities, lack of control, and waste from lapses. IoT makes the cold chain ‘intelligent’ through an ecosystem of sensors, connectivity, data analytics and process automation. Key technologies of cold chain solutions that address these gaps include:

- Real-Time Tracking & Monitoring

Miniature Bluetooth tags, RFID labels, and temperature data loggers attached to individual packages, pallets, and containers allow precise tracking of locations, ambient conditions, light or moisture exposure, and more while in transit. Operators enjoy end-to-end cargo visibility rather than just status updates at fixed points.

- Temperature & Equipment Monitoring

Wireless sensors help identify risk points for temperature fluctuations within vehicles, warehouses and storage units. Teams can quickly address issues before product quality or safety is impacted.

- Fleet Optimization & Automated Routing

IoT connectivity allows dynamic route planning and redirection of shipments based on emerging road conditions like weather or traffic. Tracker data is transmitted via cellular, Bluetooth, or LoRaWAN network to ensure seamless cold chain data visibility even in hard-to-reach locations.

- Automation & Advanced Analytics

As IoT generates vast amounts of rich sensor data, integration with cloud platforms extract actionable insights on improving process efficiency, reducing wastage, and strengthening compliance.

Cold chain vs. supply chain differences

While casual observers use “supply chain” and “cold chain” interchangeably, some crucial differences set cold storage and transport apart. For goods like metals or appliances, general supply chain practices may suffice. But fruits, dairy products and medical supplies demand stringent cold chain processes enabled by IoT capabilities.

Scope: Supply chains encompass the flow of all raw materials and products in a business ecosystem. Cold chains focus exclusively on temperature-sensitive cargo. It can be considered a small but crucial subset of the vast global supply chain industry.

Infrastructure: Cold chains require specialized storage with refrigeration equipment and fleets designed for climate control. So added costs and complexities are involved.

Sensitivities: Even minor deviations can ruin perishable foods, vaccines, chemicals etc. making diligent monitoring non-negotiable.

IoT offers advantages across modern ‘smart’ supply chains but cold chain monitoring has been its killer application so far due to the cost of goods lost being 10X more than sensor costs. Overall lack of supply chain visibility could lead to huge economic loss but for refrigerated logistics, it poses health and safety risks which makes IoT non-negotiable.

Use cases for cold chain supply logistics

Unlike the broader supply chain, the business case for IoT is very compelling in the cold chain industry due to the high-value, temperature-sensitive perishables that cannot tolerate data blindspots. Cold chain technologies are mission-critical across these industries:

Vaccine cold chains

Safe vaccination campaigns require an unbroken vaccine cold chain from labs to patients’ arms. IoT sensors extensively track storage freezers, refrigerated transport and last-mile connectivity.

Food items – fruits, vegetables, dairy, meat etc.

Chilled and frozen foods like produce, meat, dairy rely on IoT tracking and temperature control across complex farm-to-fork supply webs.

Pharma product shipments

For biologics, plasma products and clinical trial materials, real-time conditions visibility ensures stability and compliance.

Chemical/industrial temp-sensitive logistics

Some adhesives, paints and industrial chemicals also require climate controlled mobility. IoT monitoring proves indispensable.

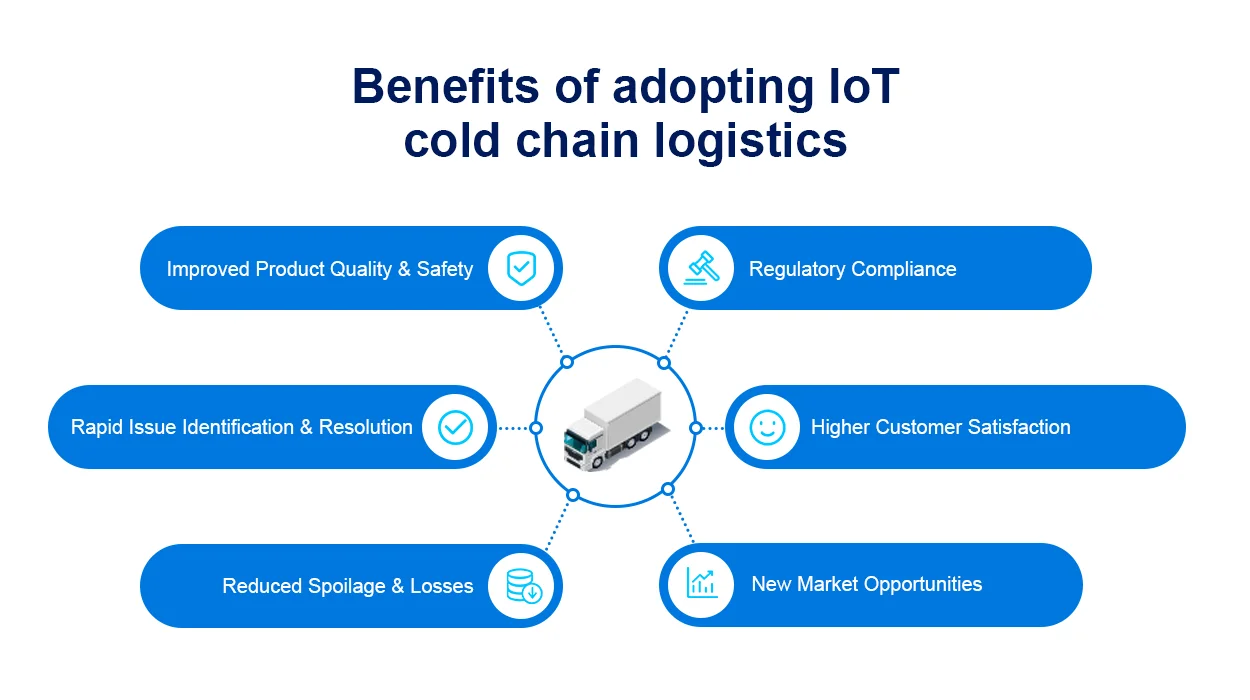

Benefits of adopting IoT cold chain logistics

Investing in IoT for refrigerated supply chain monitoring offers compelling benefits. Some major benefits of implementing cold chain transportation for businesses include:

- Improved Product Quality & Safety– Continuous temperature tracking prevents fluctuations leading to spoiled perishable goods unfit for consumption. This protects consumer health and brand reputation.

- Reduced Spoilage & Losses– By maintaining recommended temperatures, cold chain reduces degradation, contamination risks and extends shelf life. This minimizes losses due to unforeseen temperature deviations.

- Rapid Issue Identification & Resolution– Instant cold chain data alerts relevant teams to take corrective actions like opening warehouse doors or rerouting non-compliant refrigerated vehicles to prevent bigger losses.

- Regulatory Compliance– For pharmaceuticals, clinical items and select foods, unbroken cold chains are mandated by regulations for quality and public health. This prevents legal issues.

- Higher Customer Satisfaction– Reliable cold chain processes driven by IoT boost consumer trust in brand products by reducing instances of degraded quality or safety issues after point-of-sale.

- New Market Opportunities– The capacity to export perishable products globally opens avenues to lucrative overseas markets. Most countries enforce strict cold chain rules for inbound shipments.

Leveraging MOKO IoT solutions for cold chain logistics

MOKOSmart provides an integrated cold chain IoT hardware solution encompassing sensors, connectivity, and dashboards for end-to-end visibility. Our temperature humidity sensors, location beacons, door sensors capture ambient data across transit. Our gateways then send the collected data to the MOKO Cloud for real-time monitoring and analysis. When exploring IoT options, look no further than MOKOSmart – a reliable one-stop manufacturer for sensors, trackers, gateways, etc.

FAQs on cold chain logistics

– What temperature range defined as a cold chain?

2–8° Celsius (35-45°F) for pharmaceuticals, below -18°C (-0.4°F) for frozen goods and 0-15°C (32-60°F) for fresh produce generally define cold chain ranges.

– What are common cold chain tracking technologies?

Sensors, Bluetooth beacons, RFID tags, data loggers, GPS and cellular/satellite networking enable real-time visibility across refrigerated logistics.

– What goods need cold chain logistics?

Perishable items having high respiration rates like fresh foods, chemicals, flowers etc. need cold chains to arrest deterioration. Items like vaccines, biologics requiring fixed temperatures for potency also require them.

– What are the challenges of cold chain logistics?

Cold chains uniquely struggle with temperature control across transport modes, fragmented visibility, pinpointing fluctuation sources, infrastructure costs and spoilage risks.