The Internet of Things (IoT) is sweeping numerous areas of modern life. Now, IoT has spread to industrial environments as well – hence the term Industrial Internet of Things (IIoT) being used more commonly. But what exactly is the difference between IoT vs IIoT technologies? Both are considered essential for a wide range of IoT market applications. With connected smart devices vastly increasing each year, it is critical to consider the deployment factors of IoT and IIoT. In this article, we’ll compare and contrast IoT and IIoT to clarify when and why enterprises should consider their adoption.

An introduction to IIoT and IoT

The IoT market is projected to reach $805.7 billion in 2023 and is anticipated to surpass $1 trillion by 2026, according to IDC. Discrete and Process Manufacturing are set to lead IoT investments, constituting over one-third of global spending throughout the forecast period.

The common ground of IoT and IIoT

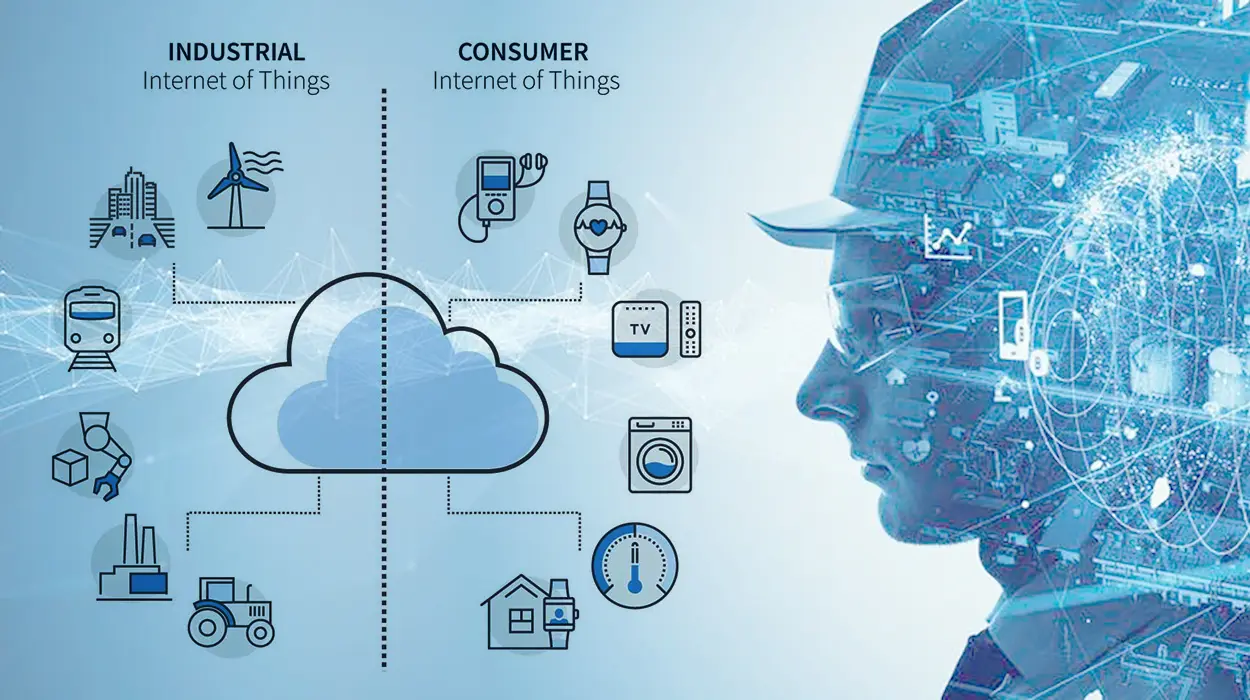

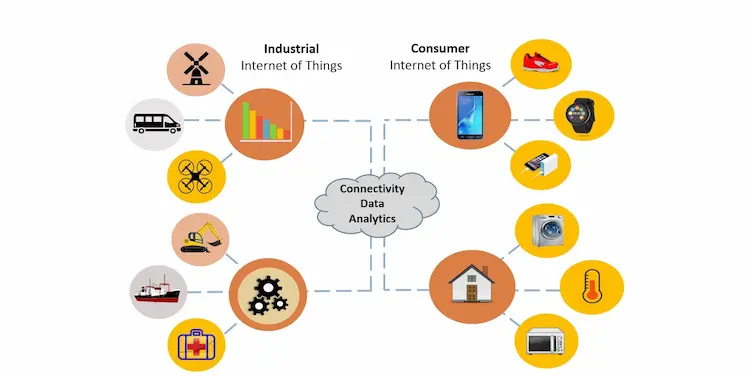

Before delving into IoT and IIoT definitions, it’s crucial to note their shared foundation. Both, with IIoT being a subset of IoT, utilize common technologies like sensors, cloud platforms, connectivity, and analytics. This similarity extends to application domains and adherence to standards and regulations. The universal technology basis for IoT applications, whether consumer-focused or industrial, comprises six domains:

- Device Hardware

- Device Software

- Communications

- Cloud Platform

- Cloud Data

- Cloud Application

What is IoT

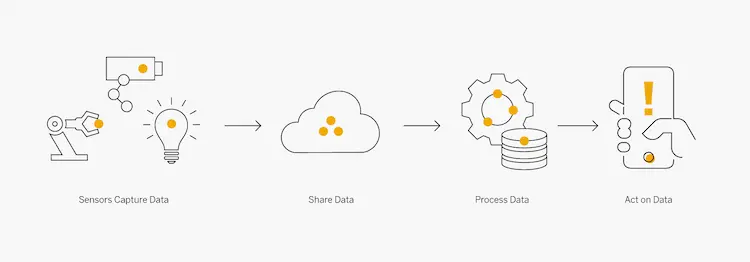

IoT refers to a decentralized network of internet-connected smart devices that can collect and share data via embedded sensors and connectivity. IoT enables devices and electronics we interact with daily – thermostats, vehicles, and more – to be monitored, accessed or controlled remotely. The core components that enable this smart connectivity include:

Embedded Sensors: Collect important data like geolocation, temperature, movement and more.

Connectivity Modules: Allow data transmission from device to the cloud servers via WiFi, cellular 4G/5G, Bluetooth and more.

Data Processing Hub: Cloud server that aggregates and processes incoming data from the sensors/devices.

User Interface: Mobile or web dashboards that provide analytics and remote control of IoT ecosystem.

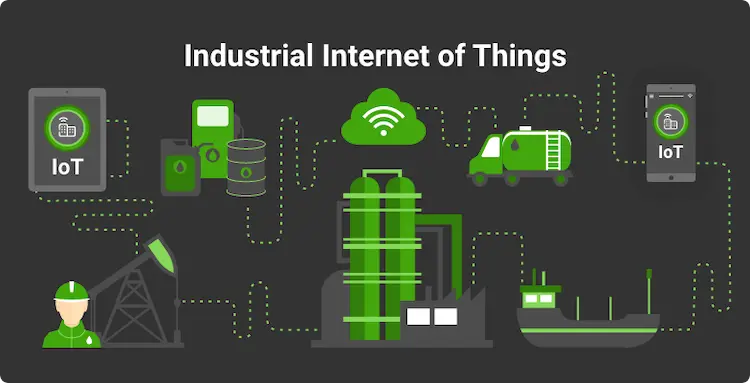

What is IIoT

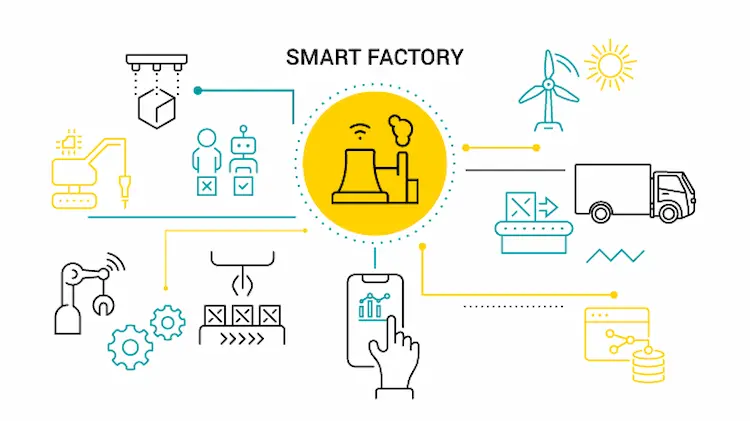

IIoT stands for Industrial Internet of Things – it refers to IoT technology applied specifically within industrial environments like factories, energy plans, field sites and more. By installing advanced automation and data collection via IIoT, industrial companies gain greater efficiency, control and insights into their operations. Unlike consumer IoT examples like smart homes, IIoT focuses on:

- Connected industrial devices like smart sensors on machinery.

- Optimizing complex operations like manufacturing and supply chains.

- Enabling crucial new technologies like predictive maintenance.

The core components providing connectivity and data exchange in IIoT architecture include:

Industrial Sensors

Wired/Wireless Connectivity

Central Server Hubs

Industrial Network Protocols

Fleet/Asset Management Software

Differences between consumer IoT vs Industrial IIoT

While IoT and IIoT share similarities in connecting devices and leveraging data, there are also clear differences between the technologies:

- Market Focus

IoT covers a variety of sectors. The IoT technology is mainly used by consumers and experts in business IoT like enterprises, healthcare, and the public sector. As IoT is applied in several distinct industries, it tends to concentrate more on universal applications. On the other hand, the IIoT technology is focused on a smaller market as experts only apply it in industrial settings. The IIoT technology is primarily used in power plants, oil and gas refineries, and manufacturing facilities.

- End Devices

The IoT and IIoT usually use different devices as they both have different focuses and objectives. Industrial IoT devices are built to offer users data on equipment where these devices, instead of working alone, integrate with existing equipment. Conversely, IoT devices are usually devices employed in daily life that can be used independently. They include smartphones, smartwatches, smart thermostats, and smart assistants. There are other IoT devices such as smart sensors that are used to develop infrastructures.

- Risk of Failing

The risk of failure in IoT devices is relatively low as these devices are only applied on a small scale. Typically, IoT devices are not utilized for restorative practices that pose a threat when they fail. Alternatively, the failure of IIoT devices and technology is more hazardous. The IIoT technology is linked over to a system; hence can pose life-threatening circumstances if one heavy machinery fails.

- Environmental Requirements

IoT devices usually function in daily environments. They are designed to endure standard temperatures and other ecological pressures. IIoT devices are more durable and reliable since they are primarily used in harsher environments, like factories, energy plants, and oil refineries. Therefore, manufacturers of IIoT devices usually craft their devices to tolerate extreme temperatures, humidity, and radio interference to ensure they provide reliable outcomes.

- Operation Safety

When dealing with most IoT systems, the safety of operations is never a concern, as these systems do not usually handle industrialized processes. In case a wrong decision is made, there are no severe security incidents that can occur due to any reason like a mistaken action or a cyber-attack.

When dealing with IIoT systems, things become entirely different. The IIoT is an essential component of the controller loop. An inappropriate action of the control process can drive the network to unstable and insecure situations. Hence, it is highly critical to have PLCs, sensors, and a communication protocol or process in the system. People can quickly lose their lives in case of one careless mistake.

- Operation reliability

Operating reliability is essential, as people’s decisions entirely depend on the result of the IoT process. An IoT system is capable of identifying and detecting deliberate or incorrect acts by an approved individual. According to the exact application, the IoT network needs to be furnished with exceptional measures to sense any manipulation and evade cyber-attacks that can produce a bad outcome.

In IIoT, this restriction is essential as the system is a component of the ICS architecture. Of most importance, reliability is a fragment of the Safety, Reliability, and Productivity (SRP) triad. Like in IoT, IIoT systems can also sense deliberate or incorrect acts by an approved individual.

- Communication Media

The architecture of an IoT ecosystem should match its communication media and protocol. As the operations are consumer-oriented, it is most likely that the system must consist of Bluetooth, WI-FI, and cellular networks. Also, it uses standard IT protocols. A comprehensive IoT network utilizes all these media where it needs to be individually cyber-secured.

As part of the ICS architecture, the IIoT network offers wireless and wired links among the ICS server, the sensor, and the PLC. From that communication media, information is conveyed to the provider of the IIoT network, where you can easily view the presence of ICS-oriented protocols. You must verify the network latency in the IIoT ecosystems that you anticipate to obtain feedback in a short time.

- Cyber Defense

As the IoT ecosystems deal with consumer-oriented end devices mounted in stores, homes, offices, bus stations, etc., cyber defense signifies a fundamental problem. These IoT devices improve public suitability; however, the technology comes with cost limitations that prevent the attachment of cyber defense measures. It is always important too;

a) Deploy an improved cyber defense for the system that connects with these devices

b) Where applicable, ensure that you update your verification measures, such as the device username and password.

c) Conduct constant scanning on your systems to sense any foreign or unauthorized devices

Nevertheless, with IIoT, things are very much different. The cyber risk is higher here, although its investment resources for retrofits and upgrades are easy to obtain. Moreover, to best practices of the IoT network already listed above, it is also essential to consider extra measures for your IIoT ecosystem.

a) Perform susceptibility analysis and retrofits to improve the physical security of your devices.

b) Use the Intrusion Detection System (IDS) to detect any anomaly condition

c) Add any other special verification measures convenient for your IIoT ecosystems

Examples of IoT applications

Here are some of the most common examples of Internet of Things technologies transforming consumer products and experiences:

Connected devices allow homeowners to remotely monitor energy consumption, control lighting/appliances, receive alerts and automate household activities.

Wearables

Internet-connected exercise trackers, smartwatches, medical monitors and more are shaping the wearables market.

Smart Cities

IoT technology underpins smart city infrastructure. Sensors can monitor traffic congestion, alert authorities about needed road maintenance or send real-time public transit updates to waiting commuters.

Smart Buildings

IoT enables cities to increase the productivity and operations of public buildings. Smart technology can be used in cities to assemble information from several systems within the building, such as lights, elevators, and air conditioning.

Smart Utilities

Sensors are integrated into smart cities’ infrastructure to improve productivity, expand maintenance programs, allow remote operations, and achieve other benefits. Sensors can be mounted in street lights, roadways, water systems, transportation networks, etc.

Connected Vehicles

Automakers are getting onboard with IoT too! Modern vehicles collect telematics data to relay nearby traffic conditions. Consumers also leverage IoT for tracking drivers, fuel efficiency and automating maintenance updates.

Examples of IIoT applications

Meanwhile in industrial environments, IIoT is proving equally transformative by optimizing complex operations, improving uptime and avoiding equipment failures. Common IIoT factory and enterprise use cases include:

Connected Robotics & Assembly Lines

Factories link robots, conveyors and assembly line components to collect production metrics. Insights improve manufacturing efficiency, output quality control and speed of design iterations.

Predictive Maintenance

Instead of reacting to equipment breakdowns, IIoT sensors detect early warning signs of wear and tear. This allows manufacturers to schedule predictive maintenance saving an estimated 12-18% over routine upkeep.

Supply Chain/Logistics

IIoT tracking devices allow enterprises to monitor product handling temperature, trailer refrigeration, location and more. This ensures timely handling and adherence to safety policies from factory to end customer.

Energy Management

Within offices or production environments, IIoT-connected HVAC, lighting sensors and other building systems reduce wasted electricity – targeting 10-15% lower energy consumption.

Advantages of leveraging IoT and IIoT

Implementing IoT or IIoT delivers quantifiable technology advantages plus harder-to-measure benefits related to customer/employee experiences, sustainability and future competitiveness.

For consumer IoT, advantages include:

– Convenience: Controls that automate our environment and daily tasks or summon services/content on-demand.

– Safety & Security Monitoring: Real-time home security alerts and entry access controls for peace of mind.

– Health & Wellness Tracking: IoT wearables provide vitals monitoring and help individuals set and achieve fitness goals.

Industrial IIoT advantages for operations and the bottom line include:

– Time and Cost Savings: Optimized processes mean faster production cycles and less waste.

– Minimized Equipment Downtime: Data insights enable predictive maintenance and near-zero loss of productivity.

– Enhanced Workplace Safety: Wearables that monitor employee biometrics plus environmental anomaly alerts.

– Sustainability: Reduced energy consumption and material waste.

Why IIoT is the backbone of Industry 4.0 transformation

IIoT stands as a core enabling technology for the digitization of manufacturing happening under the banner of Industry 4.0. By providing equipment interconnectivity and data exchange, IIoT empowers the information-driven and hyper-connected factory.

Additional Industry 4.0 technologies like industrial big data analytics, artificial intelligence, digital twin simulations and cloud-based industrial software platforms integrate directly with IIoT sensors and infrastructure. Together, these innovations enable entirely new capabilities like:

– Decentralized Production Decisions: IIoT machinery self-modifies based on operating data instead of centralized control.

– Intelligent Supply Chain Adaption: Inventory levels automatically shift based on real-time order data.

– Rapid Design Iterations: Simulated digital twin tests of new products replace physical prototypes and trial runs.

A McKinsey survey on Industry 4.0 indicates manufacturing companies are ramping up IIoT adoption to drive efficiency, expecting 15-30% improvements in labor productivity and 30-50% reductions in machine downtime. But cost optimization tells only part of the story – IIoT also unlocks game-changing innovations to serve customers better and pivot strategically.

MOKOSmart’s IoT and IIoT hardware solutions

Trusted by over 7,132+ customers globally, MOKOSmart offers a versatile lineup of IoT hardware perfectly suited for various applications. Our product portfolio includes IoT sensors, trackers, connectivity modules, gateways, and smart plugs.

MOKOSmart’s sensor offerings detect crucial environmental metrics like temperature, humidity, water leaks, and motion. Connectivity options range from WiFi, Bluetooth to Cellular and LoRa ensuring reliable transmission.

Whether you are an engineer exploring IoT solutions or software managers needing IoT end devices, MOKOSmart delivers proven IoT hardware engineered for various demands. Learn more about realizing the IoT solutions today.