In the previous article on warehouse management, we discussed the various wireless technologies and their applications for optimizing warehouse operations. Building upon that, this article delves specifically into the realm of inventory tracking technologies. In today’s fast-paced business environment, accurate inventory tracking is a crucial aspect in achieving successful warehouse management, allowing companies to have real-time visibility and control over their inventory quantities and movements, ultimately optimizing supply chain management.

MOKOSmart, a leading provider of IoT solutions, has developed a range of products tailored for inventory tracking applications. Our solutions utilize wireless technologies such as Bluetooth, RFID, and Wi-Fi to enable real-time monitoring and management of inventory. In this article, we will compare and analyze four types of inventory tracking technologies: Bluetooth, NFC, RFID, and Wi-Fi. We will examine their features, advantages, and limitations, empowering businesses to make informed decisions when choosing the most suitable technology for their inventory tracking needs. Additionally, we will discuss the importance of inventory tracking and emerging trends that will shape the future of inventory tracking technologies.

Why Inventory Tracking System is so Essential?

Efficient supply chain management heavily relies on the effective tracking of inventory. It allows businesses to have accurate visibility into their inventory levels, locations, and movements, leading to several benefits. Effective inventory tracking enables businesses to optimize stock levels, reduce carrying costs, minimize stockouts, streamline order fulfillment processes, and enhance customer satisfaction. It also aids in identifying and mitigating inventory discrepancies, theft, and loss. By having a clear understanding of inventory status in real-time, businesses can make data-driven decisions, improve operational efficiency, and maintain a competitive edge in the market.

Challenges of Inventory Tracking Solutions

While inventory tracking offers numerous benefits, it is essential to acknowledge and understand the challenges associated with it. Being aware of these challenges is crucial for businesses to effectively navigate and mitigate potential pitfalls.

Time-consuming: Traditional methods of manually tracking inventory can be labor-intensive and susceptible to mistakes. Counting and recording inventory items manually can be a labor-intensive process, leading to delays and inefficiencies.

Hard to keep track of items: In dynamic environments where items move frequently, keeping track of their locations and quantities can be challenging. This can result in discrepancies, misplaced items, or stockouts if not properly managed.

Large-scale inventories are not easy to control: As inventories grow in size, the complexity of tracking and managing them increases. Handling larger volumes of items and ensuring accurate inventory counts become more challenging tasks.

In response to these challenges, the emergence of IoT wireless technologies has revolutionized the field of inventory tracking, offering advanced capabilities and real-time visibility. In the following, we will explore a range of IoT wireless technologies that can address the challenges faced in inventory tracking, providing businesses with enhanced control and accuracy.

A Comparison Table of 4 Types of Popular Inventory Tracking Technologies

In the following sections, we will present a comprehensive comparison table of the four types of inventory tracking technologies: Bluetooth, NFC, RFID, and Wi-Fi. By analyzing their key features, range, data transfer capabilities, power requirements, and other relevant aspects, businesses can gain valuable insights into the strengths and limitations of each technology.

| TECHNOLOGY | RANGE | POWER

CONSUMPTION |

DATA

TRANSFER SPEED |

COST | USE CASES |

|---|---|---|---|---|---|

| Bluetooth | Short (10-100 meters) | Low | Moderate | Medium | Retail, Indoor Tracking, Personal Items |

| NFC | Very Short (2-20 cm) | Ultra-Low | Slow | Low | Mobile Payments, Access Control |

| RFID | Short (up to several meters) | Low | Fast | High | Logistics, Asset Tracking, Retail |

| Wi-Fi | Long (up to hundreds of meters) | Moderate | Fast | High | Large Warehouses, Manufacturing |

Detailed Information on the 4 Types of Inventory Tracking Technologies

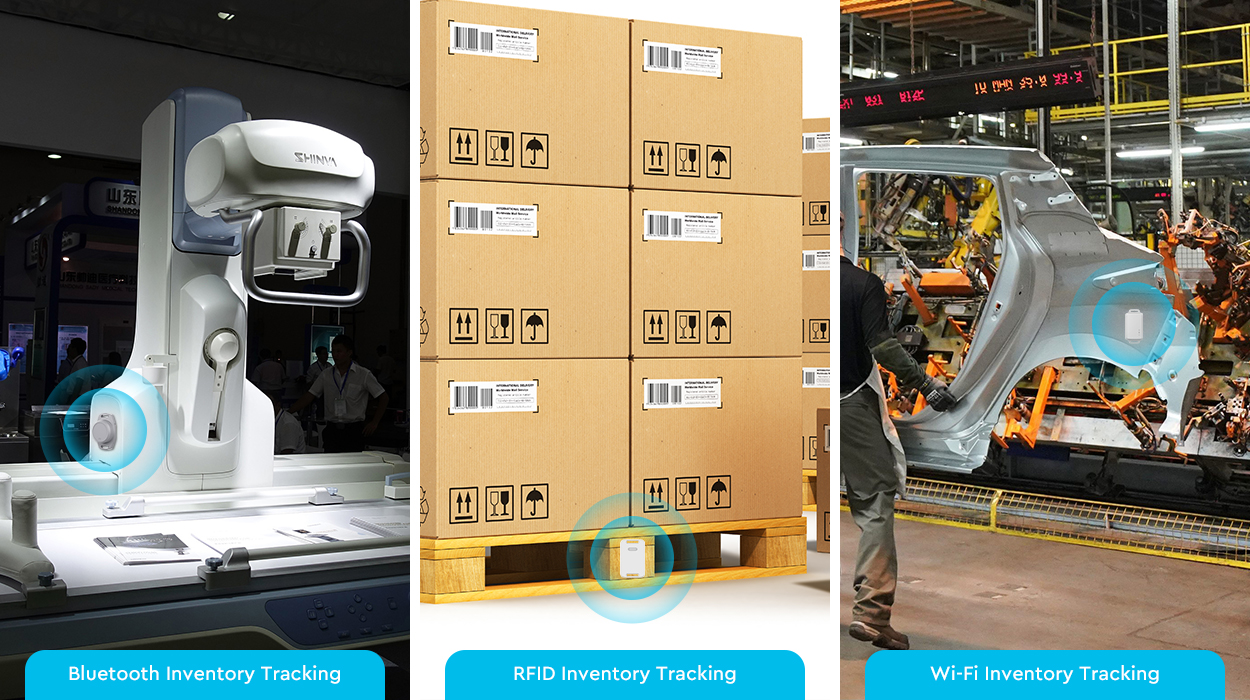

Bluetooth Inventory Tracking

Bluetooth inventory tracking utilizes Bluetooth technology to track and monitor inventory items. Bluetooth beacons or tags are attached to items, and they transmit signals that can be detected by nearby devices such as smartphones or dedicated receivers. The received signals are processed to track the movement and location of the inventory items. It is suitable for real-time tracking of inventory items in close proximity to the tracking devices.

Compared to NFC, RFID, and Wi-Fi, Bluetooth inventory tracking has a shorter range but offers several advantages. Bluetooth enjoys extensive compatibility with smartphones and various devices, facilitating seamless integration into pre-existing infrastructures. It provides non-line-of-sight tracking capabilities, allowing for tracking even when the items are not directly visible. Bluetooth inventory tracking is also cost-effective and offers low power consumption, resulting in longer battery life for the tracking devices.

NFC Inventory Tracking

NFC inventory tracking utilizes NFC technology to track inventory items. NFC tags are attached to items, and NFC-enabled devices, typically smartphones or tablets, can read the tags by bringing them in close proximity. This technology finds widespread usage in various applications, including but not limited to mobile payments and access control.

Compared to Bluetooth, RFID, and Wi-Fi, NFC inventory tracking has a shorter communication range, typically within a few centimeters. However, NFC offers the advantage of contactless communication, allowing for quick and convenient tracking. NFC tags can store more information than traditional barcodes, and they can be easily reprogrammed, making them versatile for inventory tracking purposes.

RFID Inventory Tracking

RFID inventory tracking employs RFID technology for the purpose of tracking and identifying inventory items. The process involves affixing RFID tags, which comprise a microchip and an antenna, onto the items. RFID readers emit radio waves that activate the tags, and the readers collect data from the tags, enabling tracking and monitoring.

Compared to Bluetooth, NFC, and Wi-Fi, RFID inventory tracking offers several unique advantages. It enables inventory management without the need for direct line-of-sight, and it has the capability to read multiple tags at the same time, leading to improved speed and efficiency in inventory management processes. RFID enables the collection of data in real time, minimizing the occurrence of human errors and enhancing overall accuracy. It is widely used in logistics, asset tracking, and retail industries, where large volumes of inventory need to be tracked quickly and accurately.

Wi-Fi Inventory Tracking

Wi-Fi inventory tracking utilizes Wi-Fi technology to track and monitor inventory items. Wi-Fi modules or access points are installed throughout a facility, and Wi-Fi-enabled devices or tags transmit signals that are detected by the Wi-Fi infrastructure, enabling tracking and monitoring.

Compared to Bluetooth, NFC, and RFID, Wi-Fi inventory tracking offers a longer range and faster data transfer speeds. Wi-Fi can cover larger areas, making it suitable for tracking inventory in large warehouses or manufacturing facilities. It offers effortless integration with the current Wi-Fi infrastructure, eliminating the necessity for extra hardware setup. Wi-Fi tracking systems also offer real-time data collection and enable location-based services such as geofencing and proximity alerts.

Bluetooth vs NFC vs RFID vs WIFI: Which Inventory Tracking Technology is the Most Suitable One?

Bluetooth vs NFC vs RFID vs WIFI: Pros and Cons

Bluetooth Inventory Tracking

Pros

- Low power consumption

- Non-line-of-sight tracking

- Real-time tracking

- Cost-effective

- Integration with existing infrastructure- can be easily integrated with smartphones and existing Bluetooth-enabled devices.

Cons

- Limited range

- Limited data transfer speed

NFC Inventory Tracking

Pros

- Low power consumption

- Easy integration with smartphones

- Contactless communication- allows for quick and convenient tracking without physical contact.

- Versatile tag programming- stores more information than traditional barcodes and can be easily reprogrammed for different purposes.

Cons

- Short communication range- a few centimeters.

- Limited data storage

RFID Inventory Tracking

Pros

- Non-line-of-sight tracking

- Simultaneous reading of multiple tags

- Real-time data collection

- Widely used and supported

Cons

- Power requirements- Active RFID tags require their own power source, which can impact battery life.

- Potential interference- signals can be affected by environmental factors such as metal or dense materials.

- Higher cost- RFID tags and readers can incur higher costs in comparison to other technologies.

Wi-Fi Inventory Tracking

Pros

- Long-range coverage

- Fast data transfer speeds

- Seamless integration with existing infrastructure

- Real-time data collection

- Location-based services- enables location-based services such as geofencing and proximity alerts.

Cons

- Higher power consumption

- Infrastructure and deployment complexity- Establishing a reliable Wi-Fi infrastructure and deploying access points throughout the facility can be challenging, especially in large-scale environments.

Bluetooth vs NFC vs RFID vs WIFI: Factor consideration

When choosing an inventory tracking technology, consider the following factors:

Range: Evaluate the size of the area where tracking is required. Bluetooth is suitable for smaller areas, NFC is ideal for close proximity tracking, RFID offers options for both short and long ranges, and Wi-Fi is well-suited for large warehouses or facilities.

Data transfer speed: Determine the speed at which inventory data needs to be collected and processed. Wi-Fi offers fast data transfer speeds compared to Bluetooth and NFC.

Cost: Consider the budget available for implementing the tracking system. Bluetooth is generally cost-effective, NFC offers affordable solutions, RFID costs vary based on frequency and features, and Wi-Fi may require additional investment for infrastructure.

Power consumption: Assess the power requirements and battery life of the tracking devices. Bluetooth and NFC have low power requirements, RFID’s power consumption depends on passive or active tags, and Wi-Fi may consume more power, affecting battery life.

Integration: Evaluate the compatibility of the technology with existing infrastructure and devices. Bluetooth, NFC, and Wi-Fi can integrate well with smartphones and other devices, while RFID requires dedicated readers.

Environmental factors: Take into account the surrounding conditions and environment in which the tracking technology will be implemented. Bluetooth and NFC can be susceptible to interference, RFID signals can penetrate non-metallic objects but can be affected by metals and liquids, and Wi-Fi signals can be influenced by obstacles and interference from other devices.

Industry standards: Some industries may have specific standards or requirements for inventory tracking technologies. RFID is extensively utilized across diverse industries due to its well-established standards.

Inventory Tracking Technologies Examples

Inventory tracking solution plays a crucial role in various industries and can be applied to a wide range of use cases. Here are some examples of how inventory tracking technologies, including Bluetooth, NFC, RFID, and Wi-Fi, can be utilized:

Retail: Retail businesses can benefit from inventory tracking to improve stock management, reduce out-of-stock situations, and enhance the overall customer experience. Tracking technologies can help monitor stock levels, track product movement within stores, and enable efficient inventory replenishment.

- Bluetooth: Bluetooth beacons can be placed throughout the store to track the movement of items and provide personalized offers or recommendations to customers based on their location.

- NFC: NFC tags on products can facilitate quick scanning and identification, ensuring accurate inventory management and faster checkout processes.

- RFID: RFID tags can be attached to individual products, enabling real-time inventory tracking and minimizing manual stocktaking efforts.

- Wi-Fi: Wi-Fi tracking can provide insights into customer behavior, such as popular product areas or dwell times, helping retailers optimize store layouts and product placements.

Warehouse and Logistics: Efficient inventory management is crucial for warehouses and logistics operations to ensure timely order fulfillment and minimize errors. Inventory tracking technologies can streamline processes and enhance operational efficiency.

- Bluetooth: Bluetooth-enabled scanners or handheld devices can be used to track items as they are received, stored, and dispatched within the warehouse, providing real-time inventory visibility.

- NFC: NFC tags on pallets or packages can help in identifying and tracking items during the receiving, sorting, and shipping processes, improving inventory accuracy and reducing handling errors.

- RFID: RFID tags on inventory items, pallets, or containers enable automatic tracking and monitoring of goods throughout the supply chain, optimizing inventory control and reducing stockouts or overstocks.

- Wi-Fi: Wi-Fi tracking systems can provide real-time location information of goods within the warehouse, allowing for efficient stock movement, inventory audits, and order picking.

Healthcare: In the healthcare industry, accurate inventory tracking is critical to ensure the availability of medical supplies, optimize asset utilization, and prevent stock shortages.

- Bluetooth: Bluetooth-based tracking can be employed to monitor the location and movement of medical equipment, ensuring efficient equipment utilization and minimizing search times.

- NFC: NFC tags can be attached to medical supplies, enabling quick and accurate tracking of inventory levels, expiration dates, and restocking needs.

- RFID: RFID technology can be used to track medical assets, such as equipment, medication, and surgical instruments, reducing inventory discrepancies and ensuring timely availability.

- Wi-Fi: Wi-Fi tracking systems can help healthcare facilities monitor the location of high-value assets, track inventory usage, and optimize supply chain management to ensure proper stock levels.

Manufacturing: Inventory tracking technology is crucial in manufacturing processes to monitor raw materials, work-in-progress items, and finished goods, ensuring smooth production and reducing bottlenecks.

- Bluetooth: Bluetooth beacons or tags can be used to track the movement of components, tools, and equipment within the manufacturing facility, enabling efficient inventory management and reducing downtime.

- NFC: NFC tags can be attached to work-in-progress items or containers, allowing for real-time tracking of production stages and ensuring accurate inventory control.

- RFID: RFID tags can be integrated into parts or products, facilitating automatic identification and tracking throughout the manufacturing process, improving supply chain visibility and reducing errors.

- Wi-Fi: Wi-Fi tracking systems can provide real-time location information of materials, tools, and finished goods, enabling efficient inventory management, optimizing production workflows, and reducing inventory carrying costs.

How MOKOSmart Can Help You Revolutionize Inventory Tracking?

In the previous analysis of warehouse management technologies, we mentioned some popular products from MOKOSmart, including those specifically developed for inventory tracking. Among them are the M2 Asset Tracking Beacon, which utilizes Bluetooth technology, the H5 RFID beacon, which incorporates RFID technology, and the LW008-MT Small LoRaWAN Tracker and LW001-BG PRO LoRaWAN Tracker, both utilizing LoRaWAN technology. Now, let’s delve deeper into the reasons why these products are appealing to businesses.

M2 Asset Tracking Beacon

- Range of up to 160 meters.

- Powered by a long-lasting 1000mAh lithium button battery (replaceable).

- Can store 100,000+ temperature and humidity data points and door status records, using onboard flash storage.

- Offers real-time tracking and monitoring capabilities for inventory items.

- Integrated temperature and humidity sensor.

- Integrated barometer to assist gateways with inaccurate asset tag positioning.

- Well-suited for diverse use cases, including the tracking of assets in warehouses or expansive storage facilities.

H5 RFID beacon

- Range of up to 120m.

- Additional motion sensor with trigger functionality.

- Configurable G-values, sampling rate, and sensitivity for the 3-axis accelerometer.

- Enable automatic tracking and monitoring of goods.

- IP67 waterproof standard.

- Well-suited for industries that require high-volume inventory tracking and quick item identification.

LW001-BG PRO LoRaWAN Tracker & LW008-MT Small LoRaWAN Tracker

- Provides an extended range of up to 6 km and low power consumption.

- Multiple and high-precision positioning technologies (GPS, Bluetooth, and WiFi).

- Manages and monitors inventory items in real time.

- Local data backup for uplink payloads.

- Well-suited for tracking assets across large areas, such as expansive warehouses or outdoor storage facilities.

Inventory Tracking Technologies Trends

Emerging trends in IoT inventory tracking technologies are revolutionizing how businesses manage their inventory and supply chain operations. These trends include the adoption of edge computing for faster data processing, the integration of AI and ML for intelligent decision-making, the use of blockchain for secure and transparent transactions, and the fusion of sensor data for real-time inventory visibility. Advanced data analytics techniques are being applied to gain valuable insights, while the integration of IoT devices and wireless technologies enhances connectivity and coordination. Predictive maintenance, sustainability considerations, and the integration of the broader IoT ecosystem are also shaping the future of inventory tracking. By embracing these trends, businesses can optimize their inventory management, improve efficiency, and deliver exceptional customer experiences.

Conclusion

Inventory tracking can greatly benefit from the advancements in cutting-edge IoT technologies. With these top-notch solutions, businesses can effectively monitor inventory items, collect and transmit real-time data, control product status, and make more informed decisions. It’s a cost-effective way to upgrade workflows and optimize inventory management, ultimately providing better customer service and increasing organizational competitiveness. If you’re seeking assistance and unsure about which inventory tracking technologies and products to choose, MOKOSmart can provide you with the ideal smart solutions!

Continue Reading About inventory tracking